18th,July.2019

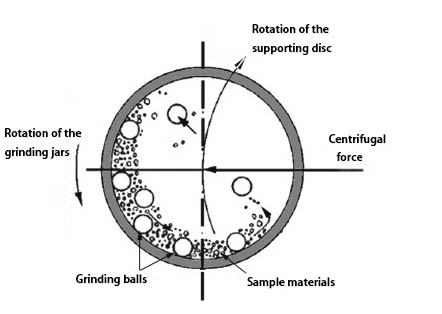

The Planetary ball mills are the most popular mills used in fine grinding of soft to hard, tough, brittle and moist materials. The grinding media have considerably high energy, because grinding stock and balls come off the inner wall of the grinding jars and the effective centrifugal force reaches up to 20 times gravitational acceleration. We may get an idea about the work principle of the planetary ball mill as below figure showing:

As we can see, In addition to the instrument settings, the grinding jars and media is also of crucial importance for a successful grinding process in planetary ball mills. How should we to choose the right jars and balls ?

1, For the classic planetary ball mill, 4 grinding jars or bowls should be selected at least with corresponding number of grinding balls. The number of grinding balls depends on the jar volume used.

2, Grinding jars material should be the same as the grinding balls.

Click here for more detailed information about tungsten carbide grinding jars&balls

3, Generally speaking, the grinding balls should be approximately 3 times larger than the largest sample particle to be ground.

4, Each grinding jar should be filled with 1/3 grinding balls, 1/3 materials to be ground, and the remaining 1/3 space served for the free movement of balls. The normal sizes of grinding jars is ranging from 25ml to 500ml. The below table provides details about usable volumes, maximum feed sizes and correct filling of the jars with grinding balls for dry milling.

Volume of grinding jar Sample Amount Max Feed Particle Size

25ml <10ml <1mm

50ml 5-20ml <3mm

80ml 10-35ml <4mm

125ml 15-50ml <4mm

250ml 25-120ml <6mm

500ml 75-220ml <10mm

Volume of Grinding jar D 5MM D10MM D15MM D20MM D30MM D40MM

25ml 100pcs 8pcs

50ml 200pcs 10pcs 7pcs 3pcs

80ml 250pcs 25pcs 10pcs 5pcs

125ml 500pcs 30pcs 18pcs 7pcs

250ml 1200pcs 50pcs 45pcs 15pcs 6pcs

500ml 2000pcs 100pcs 70pcs 25pcs 8pcs 4pcs

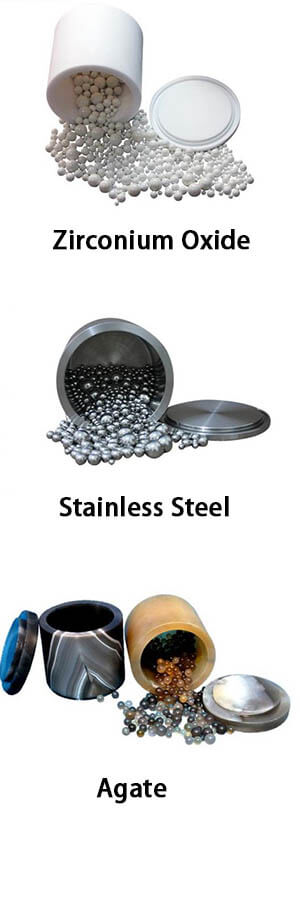

5, The heavier and larger grinding jars and grinding balls with high density, the higher the impact energy, which can shorten the grinding time. For pulverizing soft samples, materials with low to medium density should be used, whereas for hard samples, it is better to use high-density materials.

6, To achieve the best grinding results, the selection of grinding jars material mainly depends on the ground sample materials. First and foremost is that the material of grinding jars and balls must harder than the sample materials. Otherwise the jars & balls will be grounded actually by the samples during the grinding process, therefore, the sample materials will be contaminated.

Material Hardness Hardness(Mohs) Density(g/cm3) Wear Resistance Possible Contamination Application

Tungsten carbide HRA 90 9 14-14.8 g/cm3 high WC(extreme small amount) used for grinding very hard, brittle sample materials

Zirconium oxide 1250 HV 8.5 6.05 g/cm3 high ZrO2,Y2O3(extreme small amount) suitable for pulverizing medium-hard to hard and fibrous samples. It is typically used for heavy-metal-free grinding processes but also for ultrafine milling

Stainless steel ≤ 245 HB 5.5-6.3 7.7 g/cm3 medium Fe,Cr used for pulverizing medium-hard to hard and brittle samples

Agate 6.5-7 2.65 g/cm3 Low SiO2 a highly pure natural material suitable for pulverizing soft to medium-hard or fibrous samples. Due to its low-density agate is suitable for gentle grinding processes with low energy input

Sintered aluminum oxide 1750HV 8-8.5 3.9 g/cm3 medium Al₂O₃ a ceramic material suitable for grinding soft to medium-hard or fibrous samples. It is mainly used for heavy-metal-free grinding processes.

Leave A Comment