Tungsten carbide burrs, known for their exceptional hardness and durability, are essential tools in various industries. Comprising tungsten carbide, these burrs offer unparalleled precision and efficiency in shaping, grinding, and detailing tasks. In this comprehensive guide, we will delve into the world of tungsten carbide burrs, exploring their composition, types, applications, benefits, and maintenance.

Definition and Composition

Tungsten carbide burrs are cutting tools made from tungsten carbide, a compound of tungsten and carbon. This unique composition provides remarkable hardness and resistance to wear, making them ideal for precision work

Manufacturing Process

These burrs are meticulously manufactured using advanced techniques, ensuring their sharpness and longevity. Precision is key in the production process, guaranteeing high-quality tools for industrial applications.

1. Raw Material Selection:

The tungsten carbide powder is mixed with a binder material, often cobalt, to form a cohesive mixture. The ratio of tungsten carbide to binder material influences the burr’s hardness and toughness.

2. Mixing and Binding

The tungsten carbide powder is mixed with a binder material, often cobalt, to form a cohesive mixture. The ratio of tungsten carbide to binder material influences the burr’s hardness and toughness.

3. Compaction:

The mixture is then pressed into the desired shape using high-pressure machinery. This process creates a “green compact” that roughly resembles the final burr shape.

4. Sintering

The green compact is heated in a controlled atmosphere furnace in a process called sintering. During sintering, the binder material melts and fuses the tungsten carbide particles together, resulting in a solid and dense carbide structure.

5.Brazing

After the meticulous sintering process, the hard alloy rotary file enters a crucial phase known as brazing. This step involves the application of a brazing material, often a composite of copper and silver alloys, to facilitate the bonding of the hard alloy head to its steel shank.

6. Shaping and Grinding

Applications and Industries

In the metalworking industry, tungsten carbide burrs are indispensable for shaping, grinding, and deburring tasks. Their precision makes them valuable in sectors such as automotive, aerospace, and jewelry making. Woodworkers utilize these burrs for carving, shaping, and detailing, while DIY enthusiasts and hobbyists find creative applications in arts, crafts, and model making.

Benefits of Tungsten Carbide Burrs

Tungsten carbide burrs offer several advantages, including exceptional durability and longevity. They provide unmatched precision and efficiency, making tasks more manageable and reducing production time. Despite their initial investment, their extended lifespan makes them cost-effective in the long run.

Proper Usage and Maintenance

To ensure safety, users must follow guidelines and wear appropriate protective gear when using tungsten carbide burrs. Proper maintenance, including cleaning and storage, is crucial for maximizing their lifespan and maintaining their performance.

Tungsten carbide burrs are indispensable tools in various industries, offering unmatched precision and efficiency. Understanding their composition, types, applications, and benefits equips professionals and enthusiasts alike with the knowledge needed to excel in their tasks. By choosing high-quality tungsten carbide burrs from reputable brands, individuals can elevate their craftsmanship and achieve remarkable results in their work.

Explore the world of tungsten carbide burrs at Miller Carbide , and experience the difference precision tools can make in your projects.

After brazing, the burr undergoes shaping and grinding processes to achieve the precise dimensions and cutting geometry. Advanced grinding techniques are employed to sharpen the burr’s cutting edges to razor-like precision

Types of Tungsten Carbide Burrs

Tungsten carbide burrs come in a variety of shapes and configurations, each designed for specific applications:

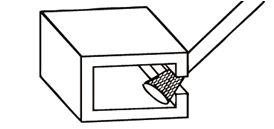

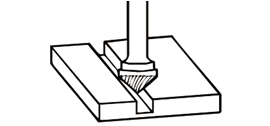

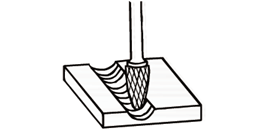

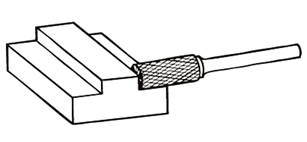

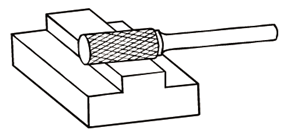

- Cylindrical Burrs: These burrs have a cylindrical shape and are used for contouring, shaping, and enlarging holes.

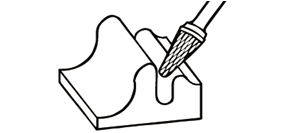

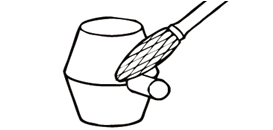

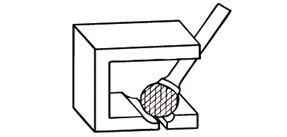

- Ball Burrs: Ball-shaped burrs are ideal for carving, sculpting, and blending edges. They provide a smooth finish on contoured surfaces.

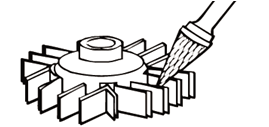

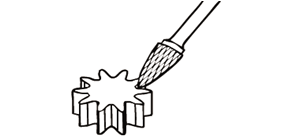

- Tree Burrs: Tree-shaped burrs feature a pointed end and are suitable for reaching tight spaces and detailed work in woodworking and metalworking.

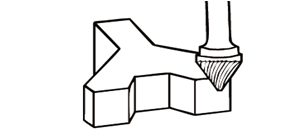

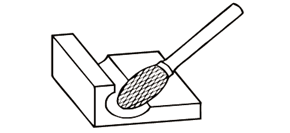

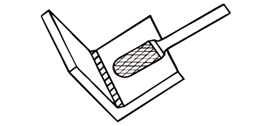

- Conical Burrs: Conical burrs taper to a point and are excellent for deburring, chamfering, and shaping concave surfaces.

- Inverted Cone Burrs: Inverted cone burrs have a rounded tip and are effective for removing material in hard-to-reach areas.

- Flame Burrs: Flame-shaped burrs have a unique shape resembling a flickering flame. They are used for sculpting and detailed carving.

- Oval Burrs: Oval-shaped burrs combine the benefits of cylindrical and ball burrs, making them versatile for various tasks.

Cylindrical Burrs

Tree Burrs

Ball Burrs

Conical Ball Burrs

Inverted Cone Burrs

Flame Burrs

Applications and Industries

In the metalworking industry, tungsten carbide burrs are indispensable for shaping, grinding, and deburring tasks. Their precision makes them valuable in sectors such as automotive, aerospace, and jewelry making. Woodworkers utilize these burrs for carving, shaping, and detailing, while DIY enthusiasts and hobbyists find creative applications in arts, crafts, and model making.

Benefits of Tungsten Carbide Burrs

Tungsten carbide burrs offer several advantages, including exceptional durability and longevity. They provide unmatched precision and efficiency, making tasks more manageable and reducing production time. Despite their initial investment, their extended lifespan makes them cost-effective in the long run.

Proper Usage and Maintenance

To ensure safety, users must follow guidelines and wear appropriate protective gear when using tungsten carbide burrs. Proper maintenance, including cleaning and storage, is crucial for maximizing their lifespan and maintaining their performance.

Tungsten carbide burrs are indispensable tools in various industries, offering unmatched precision and efficiency. Understanding their composition, types, applications, and benefits equips professionals and enthusiasts alike with the knowledge needed to excel in their tasks. By choosing high-quality tungsten carbide burrs from reputable brands, individuals can elevate their craftsmanship and achieve remarkable results in their work.

Explore the world of tungsten carbide burrs, and experience the difference precision tools can make in your projects.

Leave A Comment