26+ Years

Manufacturing experience

200+ Projects

Completed

250+ Clients

Worldwide

99.9%

Client satisfaction rate

MAKE YOUR BUDGET GO FURTHER

WITH OUR TOP-PERFORMING

CARBIDE WEAR PLATE & CUTTING RING

Wear Plates Carbide

DN230--Fit Putzmeister 10146063

Spectacle Wear Plate Carbide

DN150--Fit Putzmeister 430406

Base Plate,Carbide

DN180/200/230--Fit SCHWING 10146062

6" Housing Wear Plate Carbide

DN150--Fit Schwing 30391048

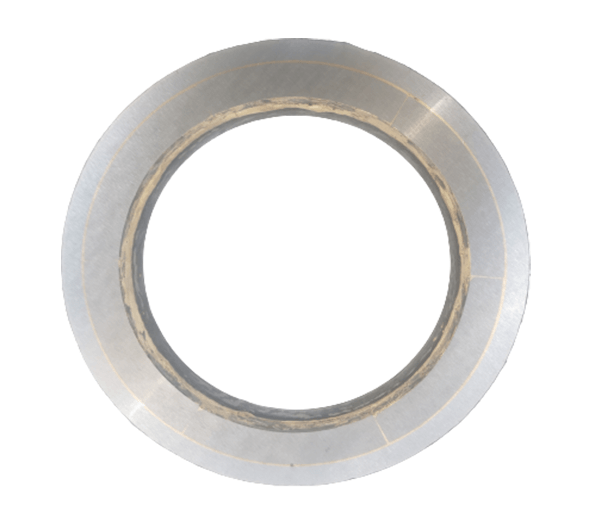

Cutting Ring-Full Carbide

DN230-Schwing Boom Wear Parts

Cutting Rings-Nornal Carbide

DN220 --Putzmeister Boom Wear Parts

Carbide Cutting Ring-TwinCircle Carbide

DN280-Schwing Boom Wear Parts

Cutting Ring-Full Carbide

DN230-Schwing Boom Wear Parts

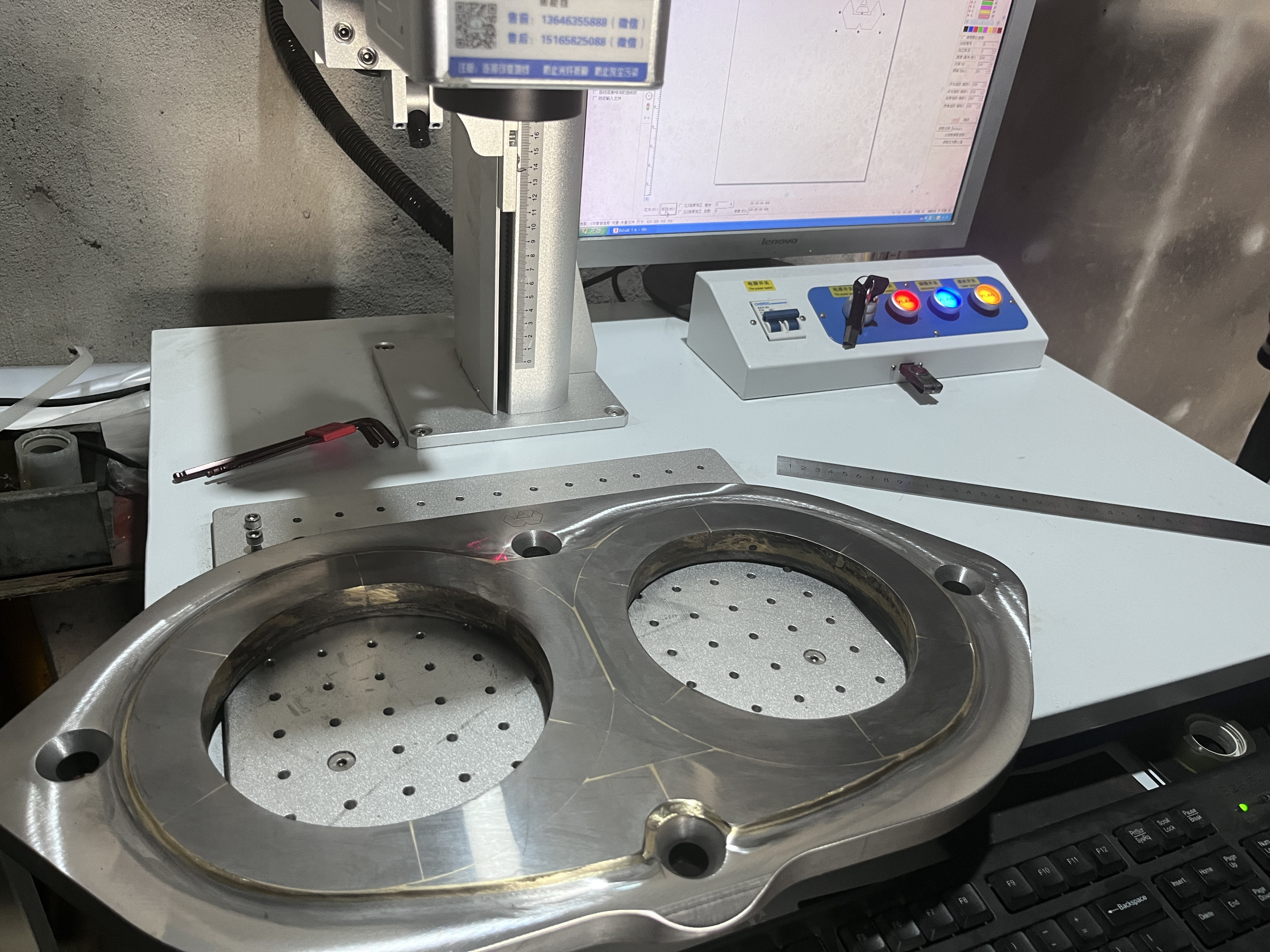

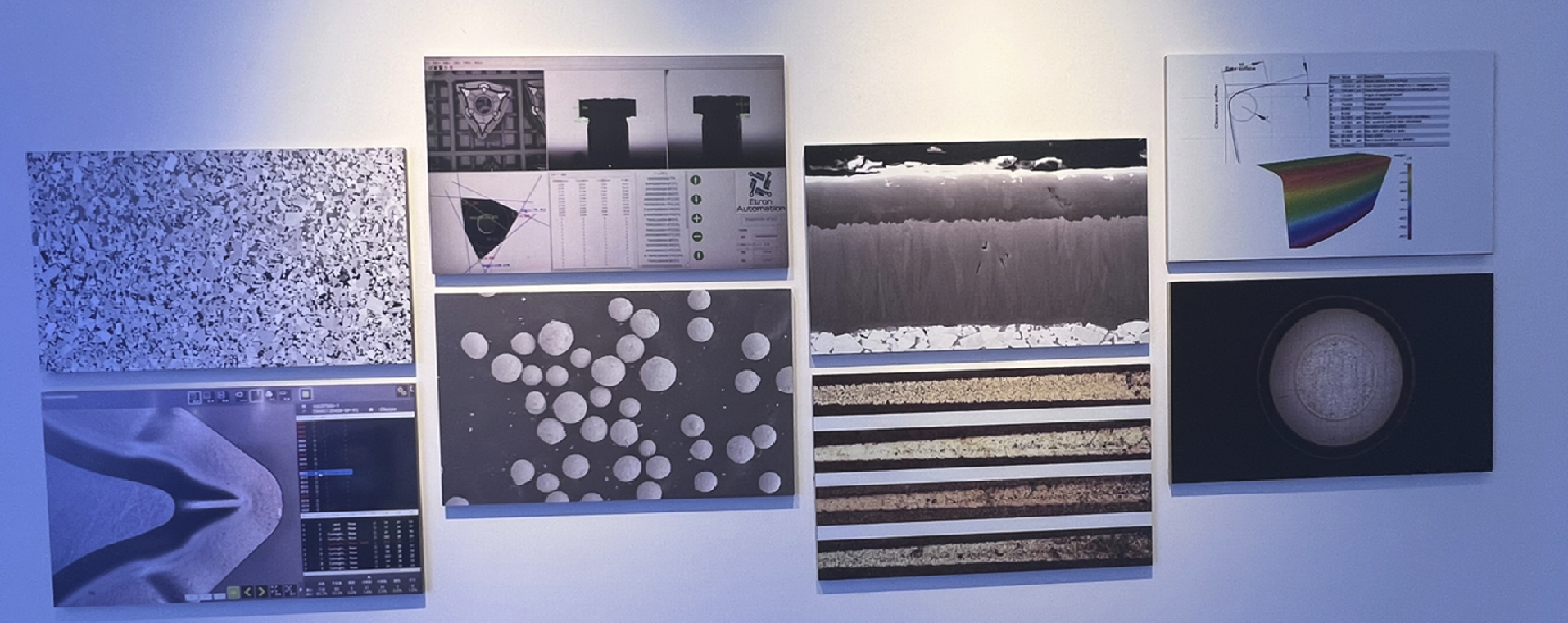

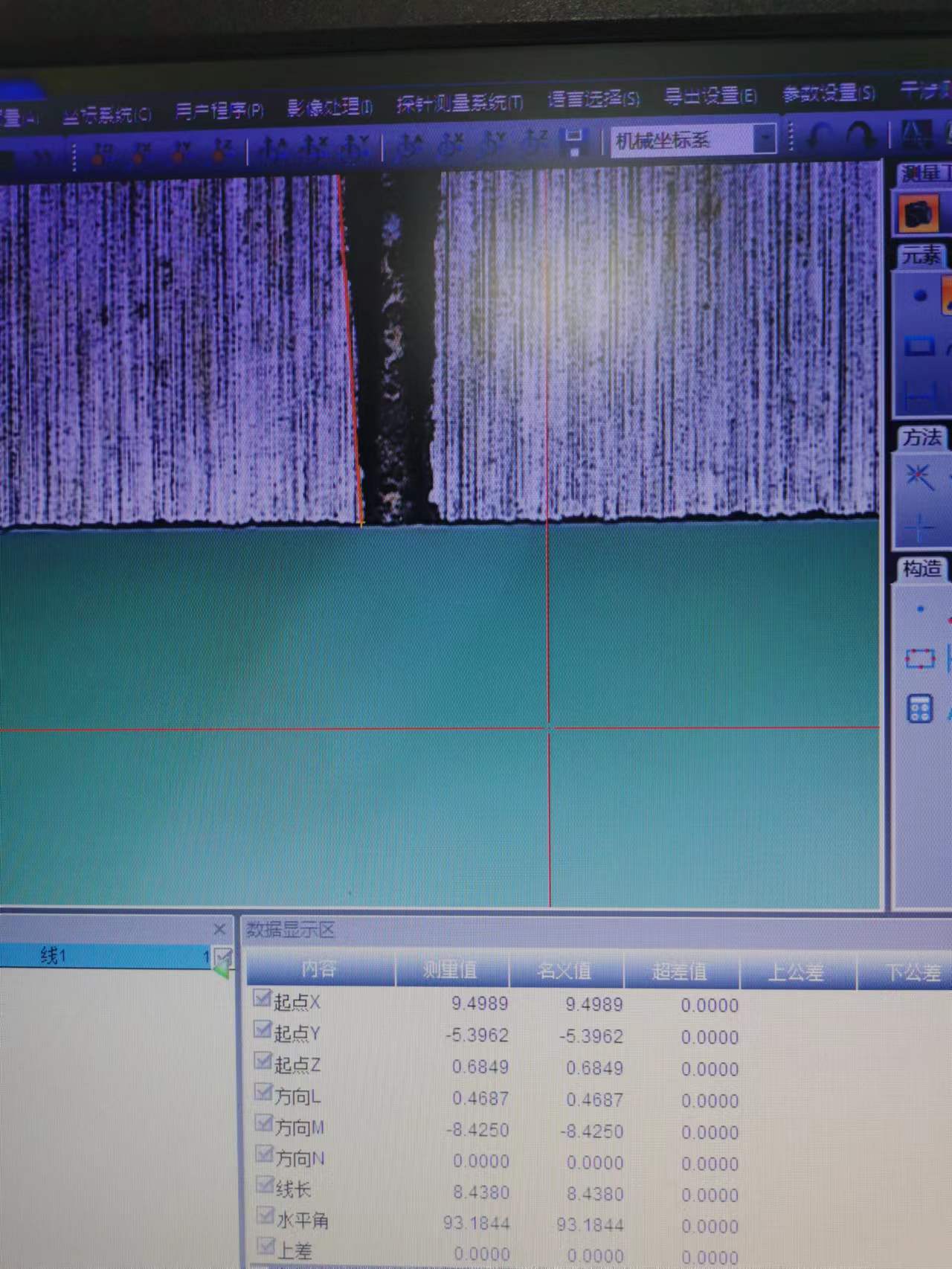

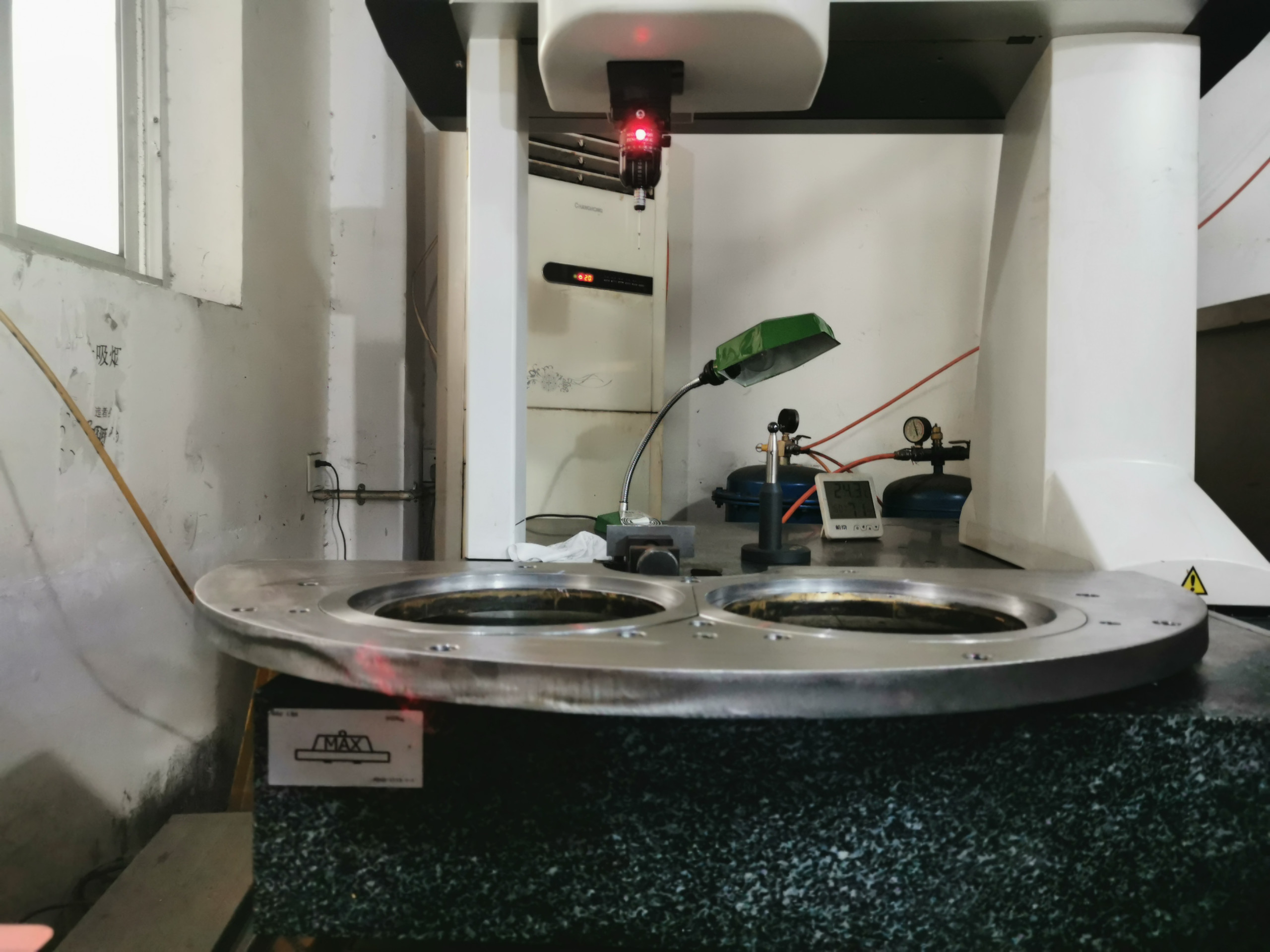

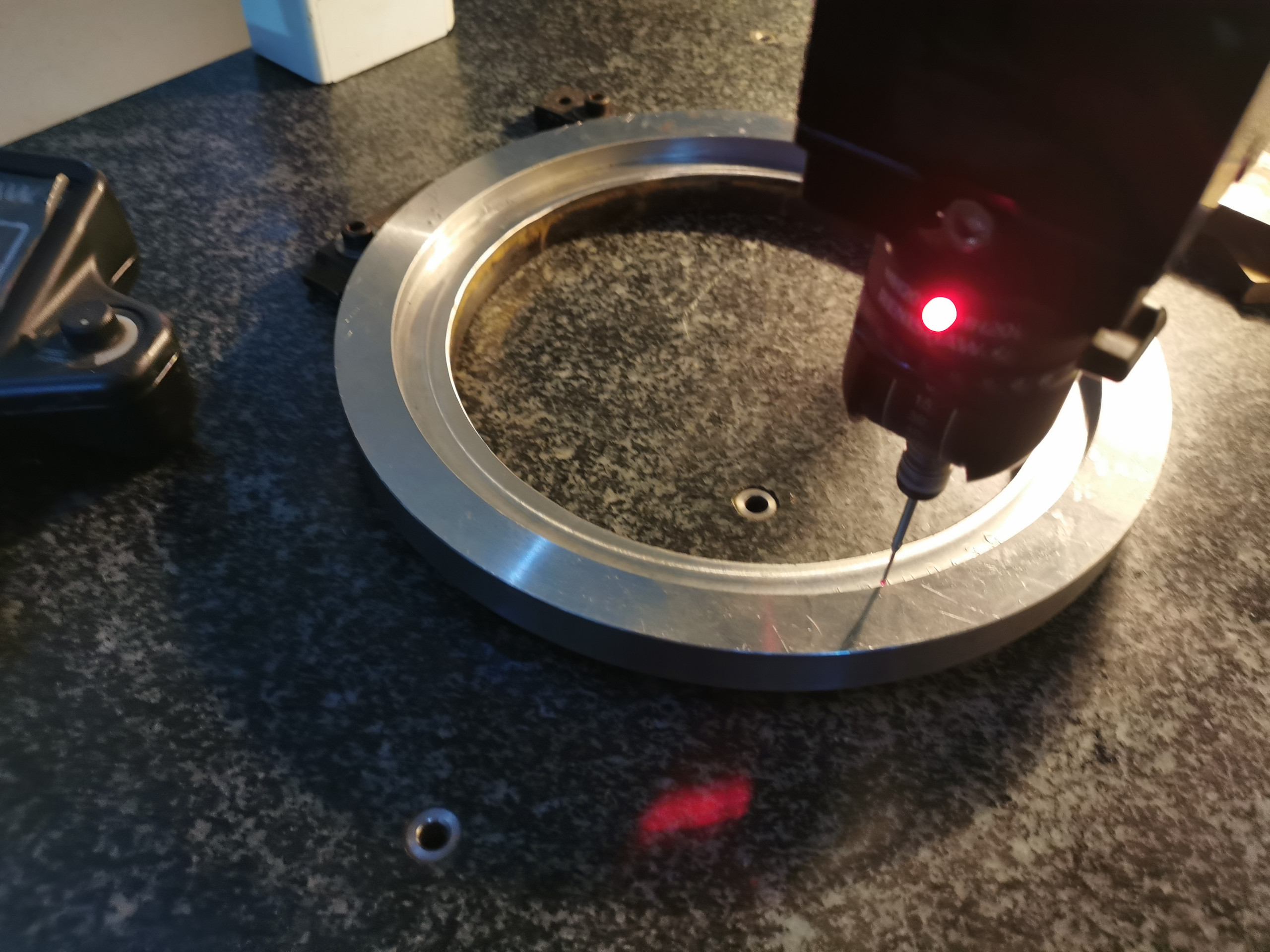

UNVEILING OUR PRECISE PRODUCTION PROCESS

Take a closer look at our meticulous production process, guaranteeing the finest craftsmanship and superior concrete pump wear plates

From raw material selection to final inspection, our production process is backed by rigorous quality control measures.Ensuring reliable concrete pump wear plates & Cutting rings.

Concrete Pump Wear Plate Summary

| Design | Materials | Advantages | Lifetime (wear plate/in cbm for reference only) |

|---|---|---|---|

| A: Normal carbide | tungsten carbide, steel plate/ring, wear-resistant electrode | good performance | 25,000-30,000 |

| B: Twin carbide | tungsten carbide, steel plate/ring, wear-resistant electrode | higher performance | 30,000-40,000 |

| C: Shape 7 carbide | shape 7 carbide segments, steel plate/ring, wear-resistant electrode | Best performance | 50,000-70,000 |

DIVERSE DESIGNS, COMPETITIVE PRICES

-EXPLORE OUR RANGE OF CUSTOM WEAR PLATES AND RINGS

At Miller Carbide, we offer a diverse selection of custom wear plate and ring designs, each engineered to deliver exceptional performance and cost-effectiveness. With our extensive range of options, you can find the perfect solution tailored to your specific needs. Our wear plates and rings come in various designs, each with its own price and lifetime characteristics, allowing you to choose the ideal balance between performance and budget. Whether you require normal carbide, twin carbide, shape 7 carbide, or another design, our team is ready to assist you in selecting the right solution for your application. Experience the versatility and competitive pricing of our custom wear plates and rings at Miller Carbide

BUDGET-ERIENDLY CARBIDE WEAR PLATE & CUTTING RINGS FOR NO-STOPWORKING

Looking for a cost-effective way to boost your business?

Expect reliable performance that keeps you moving forward with Miller Carbide‘s quality-gurateed WEAR PLATE.Our no-stop working guarantee ensures no costly downtime or disruptions to your workflow, allowing you to run your business smoothly and efficiently, without the high price tag.

At Miller Carbide, we believe in building long-term relationships based on trust, quality, and exceptional service.When you choose us as your Concrete Pump Wear Plate supplier, you gain a partner who understands your unique challenges and is dedicated to finding tailored solutions that drive your success. Trust our expertise, experience, and the reliability of our products to elevate your concrete pumping operations to new heights.

PARTNER WITH A TRUSTED CONCRETE PUMP WEAR PLATE SUPPLIER

.jpg)